-

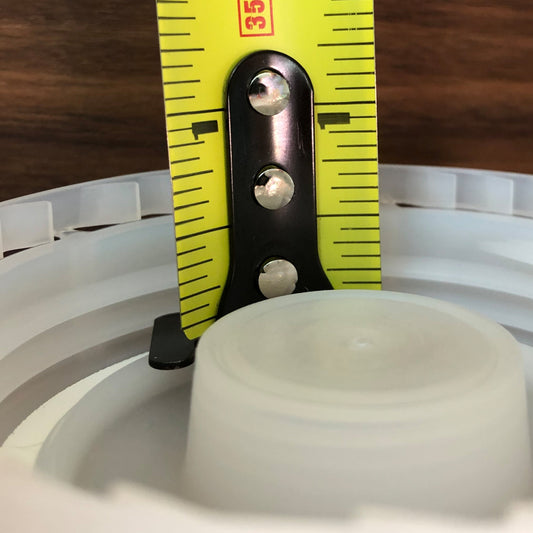

#10 Plastic Lid

Fits #10 Cans | Opaque Plastic | BPA Free Looking for an additional lid for your 5 Gallon Stackable? You've found it!Convenient plastic lid for covering your food storage once it has been opened for consumption. Great addition to your family's food storage and...- $1.49

$1.64- $1.49

- Unit price

- per

-

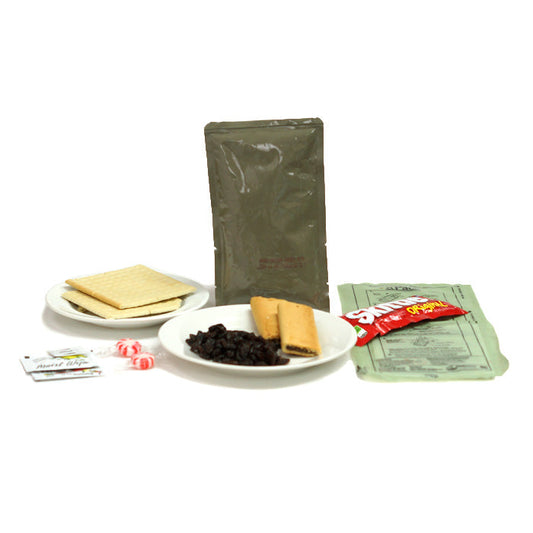

1 Month Supply - MRE Self-Heating Full Meals

Military-grade MREs - Our MREs are manufactured to deliver high-quality taste and long shelf life by a company even the US Military trusts. Quick and easy-to-store food supply option - Enjoy this 1-month supply of food that won't take up too much of your space and...- $405.99

$699.96- $405.99

- Unit price

- per

-

1 Year Supply - MRE Self-Heating Full Meals

1-Year Supply MREs | No Cooking Required | Up to 5 Year Shelf-Life •Simple food storage option - MREs are a very simple option to use for food storage and this supply will last you 1 year at 1,700 calories per day. •Don't waste valuable...- $4,619.99

$8,399.52- $4,619.99

- Unit price

- per

-

100-Gallon Stackable Water Container Essentials Kit

200 days of emergency water | BPA-free plastic | Water Preserver Included Save space and time with convenient water storage - Instead of having a huge water container or something too heavy to handle, go with the 20-count kit! It has 100 gallons of water...- $429.99

$779.99- $429.99

- Unit price

- per

-

100-Gallon Stackable Water Container Kit

200 days of emergency water | BPA-free plastic | Stack and save space Convenient Water Storage/Save Space- Rather than having a large water container that is too heavy to handle, go with our 20-count 5-gallon stackable container kit! It can store 100 gallons of water in a...- $410.00

$729.99- $410.00

- Unit price

- per

-

12-Month Emergency Food Storage Essentials Kit

Twenty-Four Buckets of Freeze Dried Emergency Food Storage Meals | Plus 100 Gallons of Water Storage Easy To Prepare Meals -The meals are very easy to prepare. With the majority of foods, all you have to do is add water - making preparation quick. Long...- $2,999.99

$8,188.92- $2,999.99

- Unit price

- per

-

20-Gallon Stackable Water Container Essentials Kit

40-day drinking water supply Essentials With Water Preserver Enough water for an emergency - Protect yourself and your family with 4 of these 5-gallon stackable water containers. Its recommended that you have one gallon of water per person per day in an emergency. This will...- $127.99

$184.99- $127.99

- Unit price

- per

-

20-Gallon Stackable Water Container Kit

40-day Drinking Water Supply Stackable Water Containers Enough water for an emergency - Protect yourself and your family with 4 of these 5-gallon stackable water containers. Its recommended that you have one gallon of water per person per day in an emergency. This will keep fresh...- $92.00

$145.99- $92.00

- Unit price

- per

-

3 Month Supply - MRE Meals

12 Case Supply of MREs With Up to 5-Year Shelf-Life | No Cooking Required Military-Grade MREs - Ameriqual delivers high-quality and long-lasting MREs that are dependable and trusted enough to be used by the US Military. Easy Emergency food Storage Option - This supply of MREs has...- $1,196.99

$2,099.88- $1,196.99

- Unit price

- per

-

3-Month Emergency Food Storage Essentials Kit

Six Buckets of Instant Freeze Dried Emergency Food Storage Meals - Plus Water Storage Easy To Prepare - The meals are very easy to prepare. With the majority of foods, all you have to do is add water - making preparation quick. LONG LASTING SHELF LIFE - This...- $1,199.99

$2,796.92- $1,199.99

- Unit price

- per

-

30-Gallon Stackable Water Container Essentials Kit

30 Days of Emergency Water Storage With Water Preserver Emergency Water Solution - It's recommended that you have 1/2 gallon of water per person per day for any emergency. This will provide you with 30 gallons (6 containers that are 5 gallons each)- about 30 days...- $168.99

$259.99- $168.99

- Unit price

- per

-

30-Gallon Stackable Water Container Kit

30 Days Emergency Water Storage Containers Emergency Water Solution - It's recommended that you have 1 gallon of water per person per day for emergency situations. This will provide you with 30 gallons (6 containers that are 5 gallons each)- about 30 days of drinking water...- $135.00

$218.99- $135.00

- Unit price

- per

-

40-Gallon Stackable Water Container Essentials Kit

80 Days of Emergency Water Storage Essentials Kit With Water Preserver Complete Emergency Water Storage Solution - It's recommended that you have 1/2 gallon of water per person per day for any emergency. This kit will provide you with 40 gallons (8 containers that are 5 gallons...- $207.99

$329.99- $207.99

- Unit price

- per

-

40-Gallon Stackable Water Container Kit

80 Days of Emergency Water Storage Container Kit Complete Emergency Water Storage Solution - It's recommended that you have 1/2 gallon of water per person per day for any emergency. This kit will provide you with 40 gallons (8 containers that are 5 gallons each)- about...- $176.00

$291.99- $176.00

- Unit price

- per

-

5-Gallon Stackable Water Container

5 Day Supply of Emergency Water Storage Container Emergency Water for Your Family - This container holds 5 gallons of drinking water, allowing you to stay hydrated during an emergency or stay safe if public water supplies become contaminated. High-quality container - This container is made in...- $24.99

$36.50- $24.99

- Unit price

- per

-

55-Gallon Water Storage Barrel

110 Days of Emergency Water Storage Barrel Non-Toxic & BPA Free - This 55-gallon water barrel is made from 100% non-toxic food-grade plastic and is BPA-free. Up to 110 days of drinking water - The 55-gallon water container holds almost 4 months of drinking water supply for...- $199.99

$249.99- $199.99

- Unit price

- per

-

6 Month Supply - MRE Self-Heating Full Meals

24 Cases of MREs Up to 5-Year Shelf-life | No Cooking Required Simple Emergency Food Storage - This supply of MREs has been put together to last you 6 months and will be readily available in any situation. Save Time Cooking - These MREs can be eaten right...- $2,349.99

$4,199.76- $2,349.99

- Unit price

- per

-

6-Month Emergency Food Storage Essentials Kit

Twelve Buckets of Freeze Dried Emergency Food Storage Meals | Plus Water Storage Containers Easy To Prepare - The meals are very easy to prepare. With the majority of foods, all you have to do is add water - making preparation quick. Long Lasting Shelf...- $1,699.99

$4,342.92- $1,699.99

- Unit price

- per

-

60-Gallon Stackable Water Container Essentials Kit

120 Days of Emergency Water Storage Container Essentials Kit With Water Preserver Space Saving Stackable Water Storage - Instead of having a huge water container or something too heavy to handle, go with the 12-count kit! It has 60 gallons of water in a small space. Each...- $285.99

$489.99- $285.99

- Unit price

- per

-

60-Gallon Stackable Water Storage Container Kit

120 days of Emergency Water Storage | Stackable Water Containers Save Space Storing Emergency water - Instead of having a huge water container or something too heavy to handle, go with the 12-count kit! It has 60 gallons of water in a small space. Each container is 5...- $258.00

$437.99- $258.00

- Unit price

- per

Recently Viewed Products

Example product title

- $19.99

- $19.99

- Unit price

- per

Example product title

- $19.99

- $19.99

- Unit price

- per

Example product title

- $19.99

- $19.99

- Unit price

- per

Example product title

- $19.99

- $19.99

- Unit price

- per

Example product title

- $19.99

- $19.99

- Unit price

- per

Example product title

- $19.99

- $19.99

- Unit price

- per

Example product title

- $19.99

- $19.99

- Unit price

- per

Example product title

- $19.99

- $19.99

- Unit price

- per

Example product title

- $19.99

- $19.99

- Unit price

- per

Example product title

- $19.99

- $19.99

- Unit price

- per

- Choosing a selection results in a full page refresh.